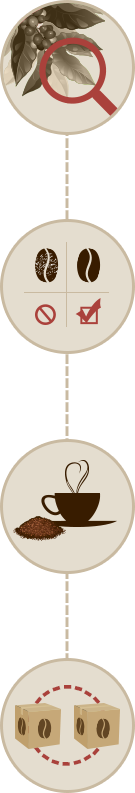

A preliminary visual analysis to verify the matching of the sample with the pre-shipment quality treated.

The quality control starts at origin, and takes place through a constant confrontation with producers in order to obtain fundamental information concerning product conditions in relation to local characteristics (microclimate and soil quality) as well as any processing undergone.

The purchased lots are always selected by our affiliates in the respective producing countries based on pre-set quality standards, and for each of the same a sample is extracted and sent to our Milan head office for a second analysis and approval.

A dedicated control system is also put in place for the shipping operations, by which the conditions of each loaded container as well as the humidity to which the coffee is exposed are always verified. In order to guarantee a secure and efficient transportation (and avoid an excessive permanence of the coffee into the metallic container), ARC relies only on the world’s most competitive and professional carriers.

Detailed matching check with the quality to be exported (Screening, Defects, Moisture).

First check on the raw sample

Upon receipt of the green coffee sample, the same is poured onto dark colored sheets and undergoes a visual as well as olfactory analysis followed by the "classification" also called "grading". Coffee classification consists of the numerical count of any defects in 300 grams of product (over ripe beans, moisture level, screen measure ecc.) and the filling out of the first part of our "Quality Sheet".

In-cup control of organoleptic parameters (sample roasting, grinding, infusion, olfactory exam, cupping preparation, tasting).

Second check on the roasted sample

In order to perform the second check, the sample is roasted in dedicated grinders especially projected to recreate the final roasting conditions. The roasting may be "Brazilian style" which is lighter than an average roasting or for "consumption" which is the standard dark brown tone. All Brazilian coffee samples are cupped "Brazilian style" (7 cups per sample) whereas all other coffees are cupped in the common for "consumption" method (5 cups per sample). The standard test is usually carried by infusion (10 g. in 150 cc. of water) and the content of each cup is roasted separately to be able to identify the cup containing any defective beans and measure accurately the cupping consistency of each lot.

Upon arrival/discharge of the goods, the lot is verified for its correspondence with the pre-shipment sample and the same analysis carried on the first sample is repeated again.

The conditions of the discharged lot are verified by introducing it into dry and clean warehouses where the competent authorities are called to check on the organoleptic suitability of the coffee in compliance with the Italian and European health regulations. At last, a final check on the outturn sample is carried to make sure about its matching with the purchased quality.

The same verification methods are also often used for samples extracted from lots dedicated to espresso blending. For espresso extractions 2 cups are tested, one sour and one sweetened, both extracted through a special machine controlled and adjusted for its pressure and temperature, calibrated to obtain the best out of that particular coffee.

It is quite hard to evaluate a mono-origin sample based on the espresso cupping, because the combination of different coffee qualities composing the espresso blend will likely alter the final result. Only the competence and the experience of a good roaster will make a difference in giving it a correct judgment.